Salt Fog - Marine Environment

No change was apparent in

NITRONIC 50 Stainless Steel

in any condition after exposure

to 5% NaCI fog at 35 C for

500 hours, or after exposure

to marine atmospheres on

the 800-foot (24.4m) lot at

Kure Beach, North Carolina,

for 7V2 years. Similar exposure

to marine atmospheres

produces light staining on

Type 316 stainless steel.

Food Handling

HPAlloys NITRONIC 50

Stainless Steel is considered

suitable for food contact use.

The National Sanitation

Foundation includes HPAlloys

NITRONIC 50 Stainless Steel

in their .'List of Acceptable

Materials for Food Contact

Surfaces."

Poly thionic Acid Resistance

Poly thionic acids are of the

general formulaH~xO6.

where x is usually 3, 4 or 5.

These acids can form readily

in petroleum refinery units,

particularly desulfurizers.

during shutdown.

Stressed U-bend

specimens of NITRONIC 50

stainless, in both the

annealed condition and after

sensitizing at 1250F (677 C)

for 1 hour, showed no trace

of cracking after exposure to

poly thionic acids for 500

hours at room temperature.

|

Pitting Resistance

|

|

|

|

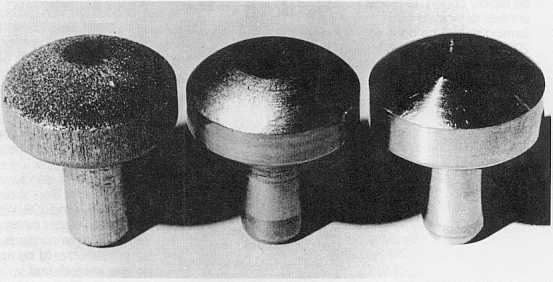

These pieces of bar were all exposed to 10% ferric chloride solution

for 50 hours at room temperature. A rubber band was placed

around each to promote crevice corrosion which sometimes occurs

in areas where the surface is shielded from oxygen. From left to

right, they are HP.AJk1N,IS IT RON IC 50 Stainless Steel, Type 316

stainless steel and Type 304 stainless steel. OnlyHP.AJkr,'s

NITRONIC 50 stainless is still bright and shiny. The Type 316 and

Type 304 stainless steels are badly pitted and show severe crevice

corrosion in the area where the rubber bands were placed.

|

|

| Type 304 |

Type 316 |

NITRONIC 50 |

Urea Production

Ammonium carbamate -an

intermediate produced

during the manufacture of

urea- is extremely

corrosive to process

equipment. Pump parts in

the process are subjected to

a combination of severe

corrosive attack, high

temperatures and cyclical

operating pressures ranging

up to 3000 psi. Some parts

made of Type 316L stainless

steel have shown surface

attack in just a few months.

A manufacturer of special

valves tested three stainless

steels in ammonium

carbamate. As shown in the

|

photograph, Type 304

stainless steel became

severely etched in two weeks

and Type 316 stainless steel

showed some corrosive

attack in all exposed areas

after six weeks. HPAlloys

NITRONIC 50 Stainless Steel

remained unaffected after six

weeks' exposure to this

aggressive medium.

HPAlloysNITRONIC 50

Stainless Steel is presently

being specified for the blocks,

plungers and related parts of

reciprocating pumps when

service requires handling

ammonium carbamate or

other corrosive materials.

|

|

|

|